- Written by: Rick Bruno

- Category: Welding Defects

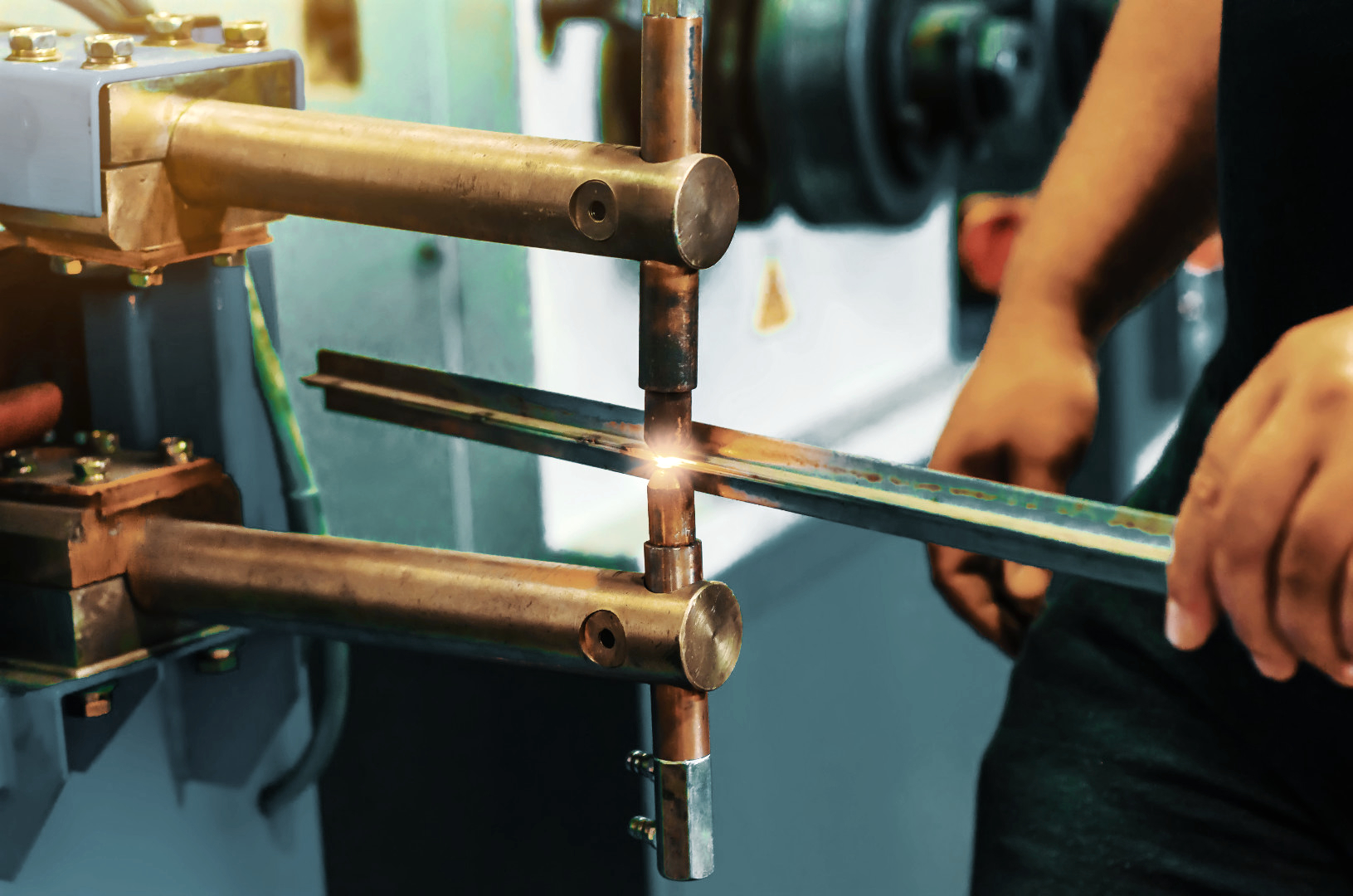

Welding, in all its forms, requires precision and patience. Issues that plague manufacturers can usually be sidestepped through adherence to checklists and careful maintenance, but sometimes problems arise despite our best-laid plans. We’re here to help you troubleshoot potential issues with your welds, inform you of why these defects arise, and what you can do to fix and/or prevent them.

In a study of common welding defects and causes of poor weld quality, the most common factor by far was fixture errors, but issues can arise from the power supply, part geometry, and a number of other variables. Some of the more common ones are listed below.